You are browsing camaro6

|

|

#1 |

Drives: 16’ 2SS A8 HBM Procharged Join Date: Jun 2017

Location: Boston

Posts: 410

|

Catch can with procharger setup

What are you guys using for catch cans with a procharger? Where is it mounted? I would like to know of a couple different options before I make up my mind. Any suggestions would be appreciated.

|

|

|

|

|

|

#2 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

You really want to understand the functions of proper crankcase evacuation on a boosted engine, and how many make mistakes by just Assuming, and that can greatly shorten your engine life as well create issues that allow more blow-by and less power when done incorrectly.

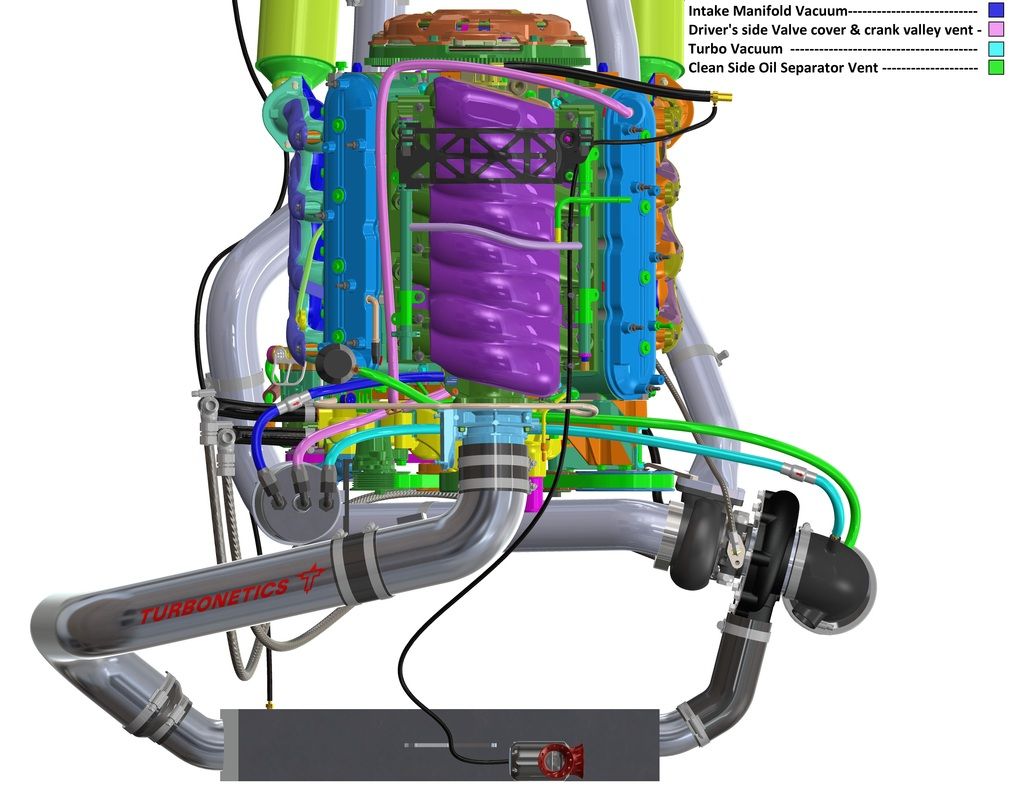

So lets first understand what crankcase evacuation is, and it is NOT allowing pressure to first build and then vent. This creates an unstable condition with the piston rings called "Ring Flutter". As all engines today use low tension piston rings to reduce parasitic friction to improve fuel economy, they must have suction below and pressure above, and if you vent your allowing pressure to build to the point of venting compounding this issue (Google search each of these terms for more detailed explanations so we don;t get too technical for many here). The best solution is of course a belt driven vacuum pump and an adjustable vacuum relief valve to achieve the goal of a steady 14-15" of vacuum present at all times (more and oil begins to be pulled from the wrist pins and rod journals) as this aids in the pistons downstroke travel as well as removes most all of the contaminants that constantly enter as blow-by. As these will quickly settle and mix with the engine oil if not removed constantly as soon as they enter, engine wear is increased. But, the belt driven pumps will not last for street use and quickly wear the vanes, seals, bearings and shafts and need to be rebuilt regularly. So we developed the next best thing. We use 2 separate evacuation suction sources and a system large enough to effectively remove and trap 95% plus of the damaging compounds you do not want accumulating in the crankcase as well as entering the combustion chamber. We use the intake manifold vacuum present at idle and deceleration to remove these and pull suction on the crankcase at all times, and the suction/vacuum created by the Venturi Effect as intake air passes the secondary suction fitting located at the turbo or centrifugal SC inlet when in boost. We use 2 special checkvalves that automatically default to the strongest suction present at any given operating mode and these also prevent boost pressure from entering the crankcase. This provides full time evacuation where any other system only uses IM vacuum so only a fraction of the time is the crankcase evacuated. Here are diagrams from Turbonetics, one of the Worlds largest Turbo manufacturers that did extensive testing and found this to be the ONLY system that properly addressed the common issues with forced induction. You can follow the same routing and if over 600 HP or 8# boost, the E2-X Ultra is the proper system to use due to the added capacity. Jessika here has a 9 second Gen6 Procharged and has used this system for the past 6 plus months and can attest to the results:  Now the diagram is of a LS engine, so you simply replace the oil fill cap with our cleanside separator and it has a line that runs to the main air filter on your procharger. The valley cover barb will run direct to the center (inlet) of our "can", one outer fitting with checkvalve flowing away to the intake manifold vacuum barb located on the driverside of the intake manifold snout, and the other outer fitting w/valve flowing away from can to the turbo or centri head unit inlet. You now have the most effective air/oil separation on the market, you are pulling evacuation suction at all times instead of just idle and deceleration, you do not allow pressure to build in the first place, and are keeping most of the contaminants that cause wear from ever reaching your engine oil. Let us know if you have any questions!  Elite Engineering USA |

|

|

|

|

|

#3 |

Drives: 2016 Camaro 2SS Join Date: Apr 2016

Location: San Diego

Posts: 66

|

Quote:

|

|

|

|

|

|

#4 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

|

|

|

|

|

|

#5 | |

Drives: 2017 Nightfall Grey Auto 2SS Join Date: Mar 2012

Location: Blue Springs MO.

Posts: 525

|

Quote:

I have that ^^^^ set up new In the box for sale  I did a custom catch can set up for my build |

|

|

|

|

|

|

#6 |

Drives: 2017 50th Anniversary 2SS Join Date: Sep 2016

Location: Jacksonville, FL

Posts: 930

|

Just how many degrees of vacuum are you able to achieve from the Venturi effect of the blower?

__________________

Former Ride: 17 Camaro 2SS, M6 - Fifty | Procharger P1SC | 3.7 Pulley | Stage 2 IC | Race Bypass | DSX FF Kit | JRE Custom E85 Flex Fuel Tune | LT4 Fuel System | JMS Voltage Booster | MSD Plug Wires | American Racing 1-7/8's LT Headers Full System Catback | Baro Breakout Harness | LT4 Map Sensor | Katech Ported TB | MMS Oil Catch Can | 160 Thermo | Solo Performance J-Pipes

|

|

|

|

|

|

#7 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

Perdieu,

Nice design, and nice aluminum welding. But you have defeated the most critical functions of the crankcase evacuation by deleting all removal and flushing of the damaging compounds that cause wear and damage. Can you share the science behind why? Also, by allowing pressure to build and vent, piston rings cannot remain stable and ring flutter occurs as well with a boosted engine. Venting has not been used Professionally for those reasons in decades, all Professional racing types pull vacuum and would never vent unless it is a basic "claimer engine" class in stock car racing where rules don't allow it. Please share the details on the thinking behind what you have. Trying to understand why some choose to defeat one of the most critical systems that keeps the engine alive and relatively wear free, especially GDI engines that experience 8-12 times the amount of raw fuel washing past the rings and entering the crankcase. Thanks! On the vacuum generated, vacuum is measured in inches, and 2-3" is max unless utilizing a special Venturi valve, then as high as 16". The main goal is to never allow pressure to build in the first place. You want to always pull suction so that the incoming filtered fresh air enters the driverside valve cover, splits to the passenger, and then is pulled down into the main portion of the crankcase flushing and replacing the contaminate laden vapors that if not removed settle and mix with the oil causing most of the wear these engines experience.

|

|

|

|

|

|

#8 |

Drives: 2016 1SS D1SC Methfed Lowered Wrapd Join Date: Apr 2016

Location: CA

Posts: 632

|

I see this come up every once in a while and its getting sort of tiring to sift through info.

I've seen Erik, ProCharger rep, mention that our cars already have a PCV system built in. I have a recirc going from that small rectangle piece on the passenger side of the engine back into my procharger filter. Why do I need this 300+ product again? What's the reason I would need this instead of, say, a mishimoto or similar catch can at half the price plus a custom bracket which I can make easily myself? Not trying to be rude here, just genuinely tired of seeing conflicting info on this specific topic. |

|

|

|

|

|

#9 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

Not ever a bother to educate.

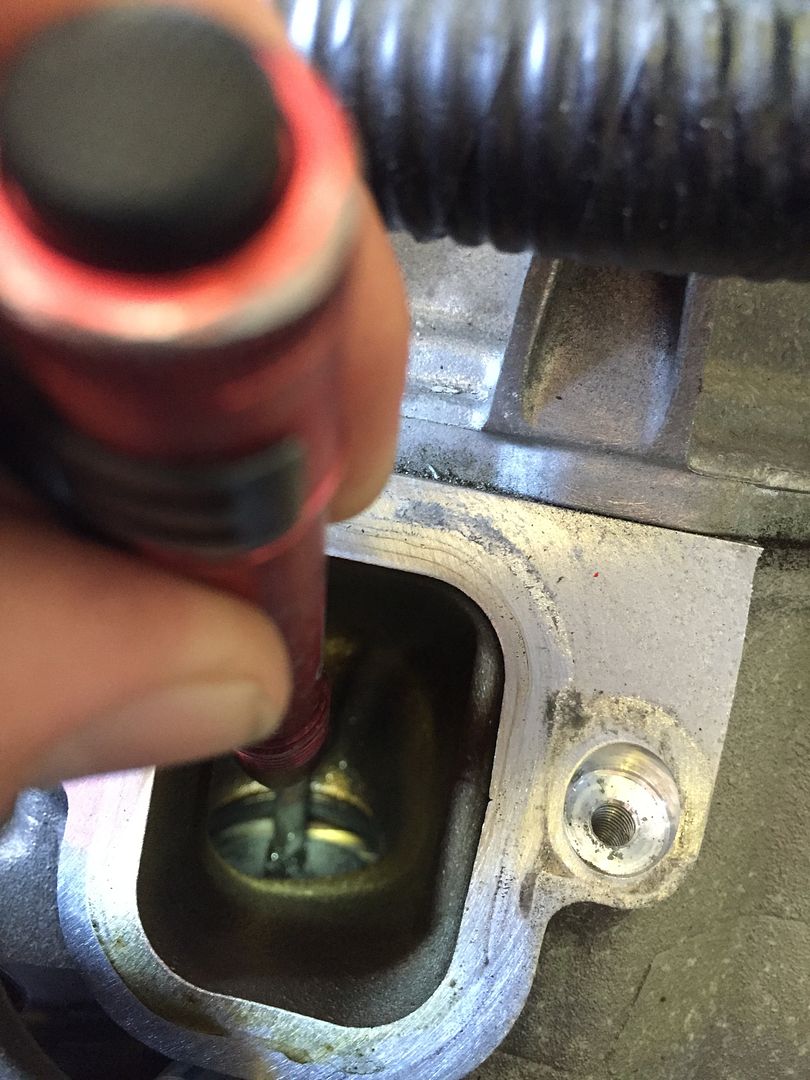

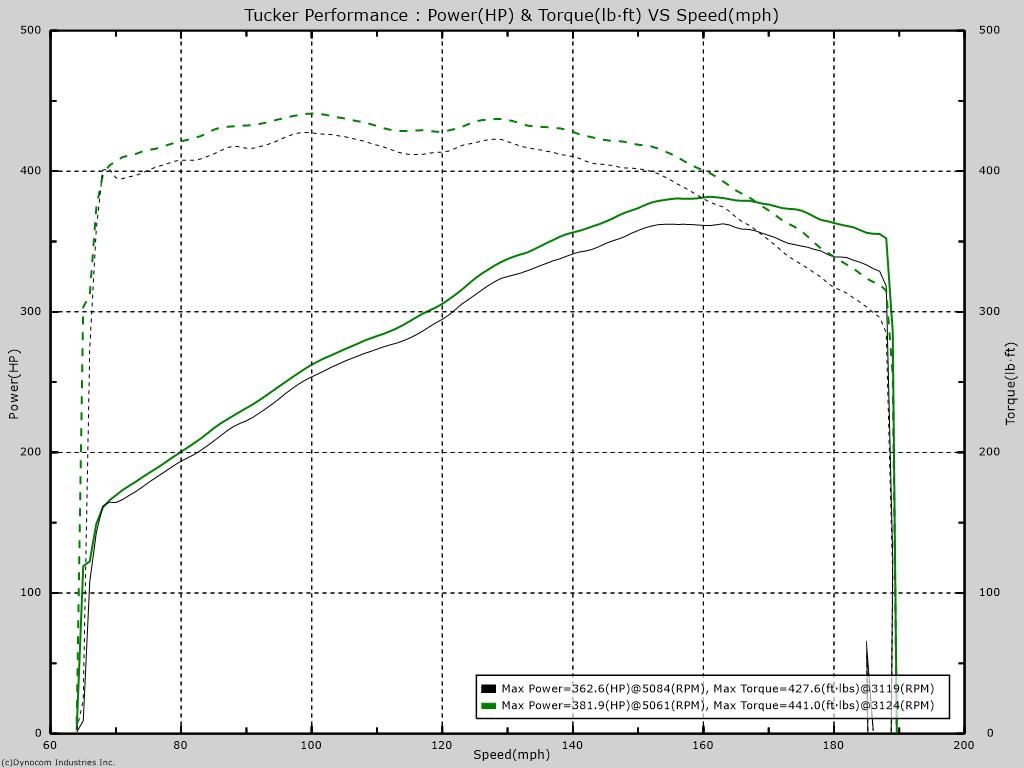

First, Procharger does nothing to provide proper crankcase evacuation and only vents into the intake portion of the system. Second, your engine is Gasoline Direct Injection and has zero fuel touching the intake valves to keep them cool and clean like the previous port injection LS engines had. Here is a picture of a LS engine with no catchcan and 142,000 miles:  and a LT1 with 19k miles on it:  And the dyno graph showing before and after cleaning the valves manually to show the loss of power that was regained: (dyno done on same day, same conditions and SAE corrected. Car owner did the manual valve cleaning and participated with dyno pulls and is an Aerospace Engineer)  So, look at a valve from your engine when new:  Note how the angles are precise and have tons of R&D into the shape, how the stem is undercut and how the tulip has a satin swirl finish. All to enhance flow and efficiency. So when you allow them to become covered in deposits, and the shape changes incoming flow and velocity of that flow is hampered and disrupted. Hence the power loss. Whats even more critical is now the valves in the ports closest to the point of ingestion are now becoming coked with larger more severe deposits than those furthest from it, so as the ECU commands the same amount of fuel for all four cylinders on that bank, the ones with most obstruction are now running richer than is optimum, and the ones furthest are running leaner than optimum so only the 1-2 in the middle of that bank now have proper A/F ratio. Then lets look at what ALL GDI engines experience. Since the fuel is introduced directly into the cylinder, and only milliseconds before TDC and spark ignition, the injectors operate at 2,000-3,000 PSI so many times the raw fuel is forced past the piston rings washing oil from the pistons and cylinder walls and diluting your engine oil and reducing it's ability to properly protect, especially with forced induction stresses added. Now we go further. With the way your Procharger comes, there is no provision for Positive Crankcase Evacuation. So as your engine was stock, at least there was the intake manifold vacuum present to positively evacuate (suck out) the vapors full of the raw fuel. water vapor, acids, and abrasive particulate matter all present in blow-by before it has a chance to settle and mix with your engine oil so wear is accelerated VS how your engine was stock. A system like ours provides full time evacuation to even better remove these vapors before they have a chance to settle and mix. And finally, today's engines all come with low tension piston rings. This is to reduce parasitic loss from friction a high tension ring causes so the automaker can meet the CAFE fuel economy standards (same with the super thin oil they recommend that does not protect nearly as well as a 15w50 does) so any pressure present in the crankcase will cause a condition known as "ring flutter" where the piston ring vibrates at a high rate reducing it's ability to seal and this more blow-by enters and power is lost. This requires suction below in the crankcase, and pressure above. Our system, unlike how Procharger does it or other catchcans being pushed, provides full time suction on the crankcase never allowing pressure to build in the first place. So, read this through several times. We know it is long, but there is no way to properly explain all the reasons and just telling you "because we said so", or "because so and so does it so you should" is not proper. We instead choose to educate and explain in detail. Ask any questions you may not be clear on and we are happy to take the time and help. But bottom line is you spent a ton of money on the car, and now a ton on the supercharger, so to not properly address the issues you face and protect that investment properly (and no, a "Vented" can is NOT providing much protection at all and will result in shortened engine life as well) the price is very inexpensive when you look at what it does. In fact no supercharger company aside form Overkill addresses any of these issues properly. Protect your investment, and become educated on all you need to know before adding anything to your build. Cheers! Elite Engineering USA. You can also feel free to email our Technical Support team direct any time: Tech@EliteEngineeringUSA.com Just facts, supporting data, and results. |

|

|

|

|

|

#10 |

Drives: 16’ 2SS A8 HBM Procharged Join Date: Jun 2017

Location: Boston

Posts: 410

|

I just installed my E2-X. I do have a question though. So with the check valves, obviously they are there so when the vacuum changes to boost, it can't push back through the can in reverse. But doesn't this mean that when in boost the can will not be sucking oil from the lower valley since there is no vacuum to do so?

|

|

|

|

|

|

#11 | |

Drives: 2016 1SS D1SC Methfed Lowered Wrapd Join Date: Apr 2016

Location: CA

Posts: 632

|

Quote:

Curious, does the fact that I am squeezing pure meth into the intake manifold change some of that? This would mean that a fuel is getting on to my valves and doing some cleaning. In that case, would adding the catchcan simply add extra peace of mind? Thanks again for that response, I appreciate it. |

|

|

|

|

|

|

#12 |

Drives: 16’ 2SS A8 HBM Procharged Join Date: Jun 2017

Location: Boston

Posts: 410

|

Nevermind. Answered my own question, I'm an idiot.

|

|

|

|

|

|

#13 | |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,381

|

Quote:

Eyefixstuff, it appears you answered your question, and there is no such thing as a "dumb question" if you don't know or are not sure of the answer. The Elite E2-X uses two separate outlets and 2 separate evacuation suction sources so the checkvalves not only prevent boost from back flowing into the crankcase, but automatically default to use the strongest suction source at any given time so pressure can never build to begin with. This is where the "vented" cans/breathers/etc. result in most of the contaminants that should be evacuated (removed) are allowed to settle and accumulate in the engine oil increasing wear and shortening engine life. Our system emulates a belt driven vacuum pump. Not as effective as that is your best solution, but vacuum pumps won't last more than a few thousand miles on the street as the vanes, bearings, seals and shafts wear rapidly. Great dialog here! Questions are the best way to understand all of this. And you NEVER want to vent or use breathers as explained above. No Professional Motorsports have "Vented" since the 1980's as technology has advanced on proper crankcase evacuation.

|

|

|

|

|

|

|

#14 | ||

Drives: 2017 Nightfall Grey Auto 2SS Join Date: Mar 2012

Location: Blue Springs MO.

Posts: 525

|

Quote:

2. It works 3. Might want to let a few of the bigger name shops know that Quote:

|

||

|

|

|

|

|

|

|

|

Post Reply

|

|

|