You are browsing camaro6

|

|

#1 |

Drives: 2019 2SS 1LE Join Date: Mar 2020

Location: Florida

Posts: 282

|

PCV/Breather question

So I'm still learning how engines work and I care about engine longevity, so PCV and valve gunk are a serious concern for me in a DI engine, I understand how the "dirty" side works, crankcase pressure that gets past the rings is vented alongside tidbits of unburnt gas and oil as the foul substance known as blowby, so something has to be done with it and is reintroduced into the manifold to be burnt for emissions/regulations and I guess it uses the vacuum from the air coming in to help vent pressure right? I already have a JVC catch can that has caught a fair bit of oil for 2000 miles.

What I don't understand is the "clean" side, I know it goes into the valve covers from the intake and before the TB, how does this work exactly? Is it moving intake air into the covers or pushing something from the covers back into the intake? I've also read that you can install a breather to prevent the recycling of whatever comes from the clean side, what would be the negatives of this? Do you just block off the intake tube if done?

__________________

Current: 2019 2SS 1LE aka "Blanc"

Previous: 2017 2LT aka "Noire" Mods: Chevrolet Performance Suspension || K&N Cold Air Intake || Borla ATAK Mufflers + Catback system || MRR 650 ZL1 replicas with squared 285/30 Michelin Pilot Sport 4S || ZZP 4 piston brake kit + braided brake lines || BMR everything (Solid/Lockout cradle bushing are a MUST in Camaros) |

|

|

|

|

|

#2 |

|

Dumb Ass Deluxe

Drives: A Tricked Out Mountain Bike Join Date: Jun 2019

Location: Arizona

Posts: 1,959

|

The high pressure (crankcase/valve covers) gets sucked into the low pressure (intake manifold). The pcx valve regulates it and the catch can tries to keep oil, water, etc out of the manifold.

__________________

|

|

|

|

|

|

#3 |

Drives: 2019 2SS 1LE Join Date: Mar 2020

Location: Florida

Posts: 282

|

Interesting, would it change anything adding a breather on the clean side and blocking it on the intake side?

__________________

Current: 2019 2SS 1LE aka "Blanc"

Previous: 2017 2LT aka "Noire" Mods: Chevrolet Performance Suspension || K&N Cold Air Intake || Borla ATAK Mufflers + Catback system || MRR 650 ZL1 replicas with squared 285/30 Michelin Pilot Sport 4S || ZZP 4 piston brake kit + braided brake lines || BMR everything (Solid/Lockout cradle bushing are a MUST in Camaros) |

|

|

|

|

|

#4 | |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,382

|

Several things to understand about crankcase evacuation and catchcans. First, ALL cans will trap what appears to be a fair amount, but 99% of those on the market trap less than 30% of the total gunk you don't want ingested. So for GDI engines that cannot tolerate these like the port injection engines they replaced these will do little to benefit your engine. Only a few designs will actually trap most of this preventing most of the issues they all suffer from.

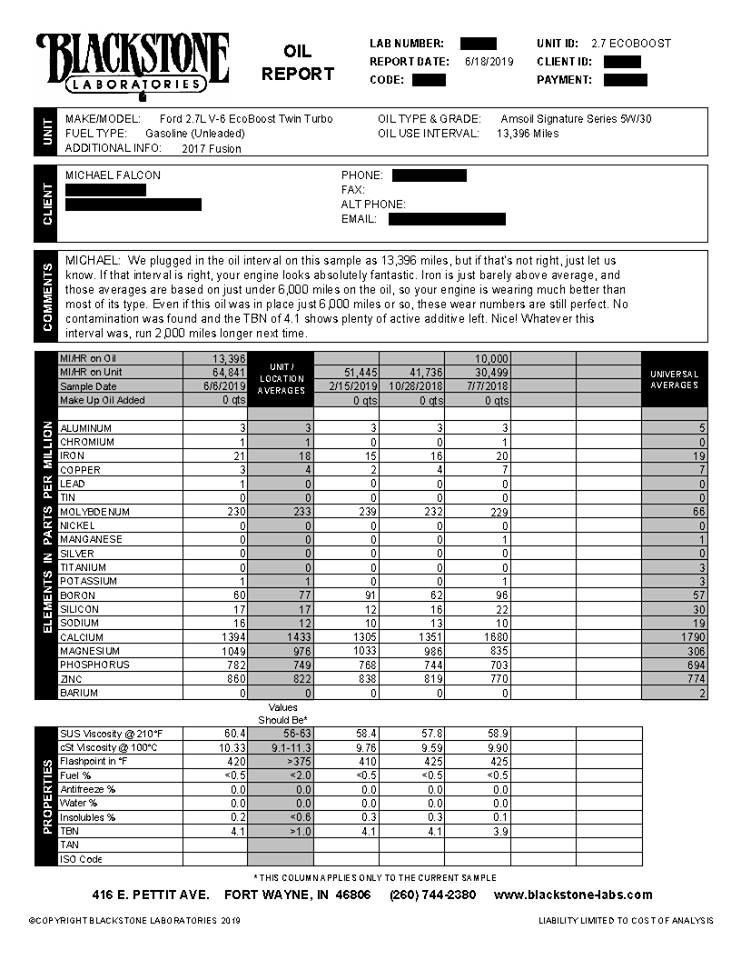

Now on to the PCV system. Pressure venting is not what occurs, and here is how the average PCV system works: So as you can see, suction is pulled on the crankcase to keep it free of the blow-by that is constantly entering the crankcase. All engines experience a certain amount. So the PCV system uses the vacuum present (in NA engines, FI can have a few variations, and the new LGX V6 has only passive, which is causing engines to wear out prematurely) in the intake manifold to pull filtered fresh MAF metered air into one bank (for a V configuration) or one portion (for an inline engine) of the crankcase to flush and make up for the foul/dirty contaminant laden vapors being evacuated (sucked out) the opposite bank or portion of the crankcase. This removes much of the substances that are part of the blow-by and reduces engine wear. These consists mainly of: Water and acids (mainly sulfuric), raw fuel (the unburnt gasoline that the super high pressures of a DI system push past the rings), and oil that is saturated with abrasive particulate matter (mainly soot, ash, and carbon). So if you would in anyway defeat or break the system, these critical functions to the engine living a long life, engine wear increases dramatically and life shortens. So you never want to put a breather or block off any of it. You would want to improve the functions to reduce wear and extend engine life. So, what are the shortfalls of the OEM PCV systems? The biggest is they do not filter and trap any of these contaminants. So they are ingested as part of the intake air charge and burnt in the combustion process. This causes detonation and the resulting knock retard as the ECU detects this and pulls timing to protect the engine. So power is lost as well as efficiency. This results in piston rings and grooves gumming up and not being able to move freely to seal properly and oil consumption and less power is the result. Intake valve coking also reduces the amount of intake air charge reaching the combustion chamber in the proer amounts and power and efficiency also suffer from this. The other issue is they mainly use ONLY intake manifold vacuum for evacuation, and this is only available at idle, light cruise, and deceleration. Anytime you accelerate the vacuum drops to below usable levels so pressure can and does build during these periods, so you improve it by adding an alternate evacuation suction source. In our case we use vacuum generated by the Venturi Effect. We use a series of special checkvalves to automatically open and close as needed to automatically default to use the strongest suction source available no matter the mode of operation. So, as our Patented design traps app. 95% where most allow 70% plus to still pass through to be ingested, not only is the valve coking prevented up to 85%, oil stays cleaner longer and wear is greatly decreased. KR is reduced or eliminated as only air and fuel are entering the combustion chamber, power and efficiency increase (8-10% MPG increase on average from KR being reduced and a cleaner burn producing more energy), power is a slight gain, so not a reason to install one, but a gain just the same. So how dramatic of an effect does a system like this have on your oil? Study the comments on this oil analysis. Note the lab techs comments. This is a GDI twin turbo running over 20# of boost. FI produces more blow-by and more damaging substances than NA, and still we see this impact. Over 13,000 miles on the oil:  So there are things you can do to care for your GDI engine, and the first thing is a good full synthetic oil only, and not the super thin viscosity the owners manual specs call for as the fuel dilution is 8-12 times that of the past engines and the already too thin of oil can barely protect. |

|

|

|

|

|

|

#5 |

Drives: 2016 2SS Convertible Join Date: May 2012

Location: St. Louis, MO

Posts: 1,711

|

The clean side draws fresh air from the air filter through the MAF. Adding a breather and blocking the intake would change the air/fuel ratio because you’re drawing unmetered air into the intake.

|

|

|

|

|

|

#6 | |

Drives: 2019 2SS 1LE Join Date: Mar 2020

Location: Florida

Posts: 282

|

Quote:

Quote:

__________________

Current: 2019 2SS 1LE aka "Blanc"

Previous: 2017 2LT aka "Noire" Mods: Chevrolet Performance Suspension || K&N Cold Air Intake || Borla ATAK Mufflers + Catback system || MRR 650 ZL1 replicas with squared 285/30 Michelin Pilot Sport 4S || ZZP 4 piston brake kit + braided brake lines || BMR everything (Solid/Lockout cradle bushing are a MUST in Camaros) |

|

|

|

|

|

|

#7 |

Drives: 2010 Camaro Join Date: Nov 2009

Location: Denver

Posts: 1,382

|

Xaxas,

What part of Florida are you in? We have our R&D partner near Sarasota/Tampa you could visit for a good crash course on all of this, and they would install a system on yours no charge, just purchase our system. To answer your question, and this is far to common, most mistakenly assume the crankcase should be under pressure and you NEVER want that. You always want suction resent so pressure can't build to begin with. And here is how the fresh/clean side of the PCV system works. Filtered fresh air should always be drawn IN to the crankcase. It passes first the air filter, then the MAF sensor (as this incoming air ultimately becomes part of the air/fuel mixture in the combustion chamber), then incorporated into the MAF is the IAT (Intake Air Temp sensor), and then the MAP sensor. So before any of it reaches the combustion chamber it is measured by each of those sensors so the ECU can determine the amount of fuel, ignition timing, and more that is needed to achieve the correct targeted A/F ratio. From there the spent exhaust gasses pass the upstream O2 senors (sensors 1) and this data lets the ECU know what needs to be done to meet the pre-set parameters in the tune. If it's lean, more fuel is added. If rich, some is taken away. So, when you mistakenly assume pressure is always going to be present, and think "I'll just put a breather here to release pressure and all will be fine". Most have this mindset as there has been no training in automotive tech schools for decades on the PCV system and all it does. So when you do this, at idle and deceleration and light cruise, the intake manifold produces the vacuum needed for evacuation (a proper system remember pulls suction on the crankcase, if you allow pressure the rings can't remain stable and seal properly and all sorts of negative issues). So it will pull in air that has NOT passed the MAF/IAT/MAP sensors so it confuses the ECU because none of the data coming in matches the tables as expected in the tune, so to protect the engine it adds more fuel. Then the upstream O2's tell the ECU it is too rich, so it takes fuel away. It will show in a scan short term trims adding and subtracting fuel so things are far from ideal. So we NEVER vent or use breathers (at least the few that understand this). Those that do vent are using technology from the pre 1960's and that leaves most of the wear and damage causing substances in the crankcase to mix with the oil and attack the metal internal parts and more. Here is what a sample from our systems consists of when spun in a centrifuge and then analysised in the lab:  This consists mainly of 70% water and acids. 23% is raw unburnt fuel 7% is actually oil, but it is saturated with the wear and damage causing soot, ash. and carbon. The abrasive substances that cause wear. So these would have been simply ingested without our system installed. Re watch that video a few times to understand better, and ask questions on any part not totally clear. Education is key as you should never blindly make a decision based on an add or because someone else told you to. Understand each function the PCV system provides (only one is pollution related) and how each affected part of the engine relies on one or more. I mentioned the piston rings and retaining stability. In engines of old (prior to the 1990's mainly) all had a high tension piston ring so this was not an issue, but as more demands of better fuel economy popped up, several changes were made. One is the piston rings were now similar to what we had been doing with race engines for decades. We used lighter low tension piston rings and today that's standard. That frees up HP and increases fuel economy, as well as running far too thin of oils to properly protect. So, all piston rings are now low tension, but several factors are critical to maintain stability, and the one we can control is the need for pressure above the rings and suction below. We are one of the only systems that provides this. Lots more to learn that were happy to share. |

|

|

|

|

|

#8 | |||

Drives: 2019 2SS 1LE Join Date: Mar 2020

Location: Florida

Posts: 282

|

Quote:

Quote:

Quote:

__________________

Current: 2019 2SS 1LE aka "Blanc"

Previous: 2017 2LT aka "Noire" Mods: Chevrolet Performance Suspension || K&N Cold Air Intake || Borla ATAK Mufflers + Catback system || MRR 650 ZL1 replicas with squared 285/30 Michelin Pilot Sport 4S || ZZP 4 piston brake kit + braided brake lines || BMR everything (Solid/Lockout cradle bushing are a MUST in Camaros) |

|||

|

|

|

|

|

#9 |

Drives: 2018 Camaro SS 1LE Join Date: Aug 2018

Location: Tampa Florida

Posts: 1,980

|

I see a lot of going running a filter for the fresh air crank case breather (middle fitting on the box), especially the guys running an OTR that no longer have the CAI elbow port.

__________________

2000 Miata - aventi storm wheels, roll bar.

2019 Mustang GT pp1 - svt pp2 wheels, mbrp cat back, sync 3 upgrade, p1x procharger + stg2 intercooler. 2018 Colorado zr2 - zr2 sport bar, showcase spare tire. 2018 Camaro SS 1LE - GM cai, black bowties, suede knee bolsters, 1le plate frame, black fuel door, dark tails + 3rd brake light, euro side markers + led's, GM all weather floor mats, velossatech big mouth, GM strut brace. 2017 Corvette Grandsport (sold) - untouched. 2006 GTO (sold) - iat relocation, air box mod, monero side marker lights.  |

|

|

|

|

|

#10 | |

Drives: 2017 2SS, 50th pkg, M6, MRC, NPP Join Date: Jan 2016

Location: Ocean City, NJ

Posts: 3,181

|

Quote:

One of the other problems I see with installing a "breather" to vent pressure from the middle position on the air/oil separator is that the vented gases are going to contain some atomized oil. Eventually that will coat the backside of the paper pleats on your "breather." This type of filter is not designed to be oil-soaked. Once soaked, where does the pressure go? Not a good solution. |

|

|

|

|

|

|

#11 |

Drives: 2016 1SS NFG A8 Join Date: Aug 2017

Location: 46804

Posts: 6,800

|

The filter still vents saturated but I just buy a replacement filter at that point.

__________________

2016 NFG 1SS A8

Options-2SS Leather/NPP Perf. mods-Whipple 2.9/Fuel System/Flex Fuel/103mm TB/Rotofab Big Gulp/Cat Deletes/Corsa NPP Per. times- 10.5 @ 137 w/ 1.8 60ft Full weight on 20's 1200DA |

|

|

|

|

|

#12 |

Drives: 2017 Camaro 2SS Nightfall Gray 1LE Join Date: Mar 2017

Location: SoCal

Posts: 86

|

I might be misunderstanding what your goal is. The clean side is called that because there is an air/oil separator on that cylinder bank and there isn't on the other cylinder bank. This always confused me because GM was smart enough to realize they needed an air / oil separator but only put it on one cylinder bank. The other cylinder bank continues to have one of the main problems with most current GDI engines; there is no fuel flowing over the valves to clean the "snot" (air/oil/acid/water/etc.) off before it cokes (hardens) and causes valve sealing issues. The valves not sealing causes all manor of issues. I read a GDI white paper were a 4 cylinder turbo motor failed with a little over 8,000 miles on it. Probably because the increased pressure with a partially open valve caused it to go boom, catastrophic detonation event.

I use a Mishimoto catch can on the dirty cylinder bank to catch the snot and prevent the buildup on the valves that causes sealing issues. The fundamental idea behind a catch can is not to change the flow characteristics of the PCV system. But to simply remove the snot from that flow before it returns to the air intake. On the topic of oil. I would not stray from the GM recommended oil. They chose it for a reason. The LT1 engine has extremely tight tolerances, probably too tight, like ring caps at .008. This makes it so you must be extremely cautious using any kind of forced induction (FI) power adder. If boost pressure gets too high (above 7-10 lbs.) the rings have no room to expand and bang. Some people get lucky and their engine doesn’t fail. Our Camaros came with a track warranty if you followed GM’s guidelines. Originally, that was to change your oil to 0w-40 while on the track and put it back to 5w-30 for on road use. They found that the 0w-40 was overheating catalytic converters causing them to melt. I image that could be caused by a lack of air flow in traffic or whatever. When Mobil 1 developed the 0w-40 ESP, GM changed the recommended oil for all applications, road and track. ESP (Emission System Protection) prevented catalytic converters from melting, yeah! You are obviously most welcome to do as you wish but understand that if you don’t run the recommended oil GM will have cause to deny any engine related warranty claim. This is what I have been lead to believe through this forum, experience, and other technical resources. All comments and ideas expressed herein are my humble opinion and should be regarded accordingly. |

|

|

|

|

|

#13 | |

Drives: 2023 1SS Radiant A10 63 427 Impala Join Date: Feb 2016

Location: central Maryland

Posts: 93

|

happy to see Elite Engineering here.

I bought your CC-300R-V6L can for my V6 many years ago. worked well and I kept it when the car was sold.

I mounted it to my 2021 LT1 and it worked well. I now have it on the 2023 LT1. I want to know: Am I truly doing it right or, Is there a better one available nowadays? thanks much for a great product. Over the years, my can made a believer out of many skeptical friends and technicians. You Got a better one that fits the LT1? Quote:

|

|

|

|

|

|

|

#14 | |

Drives: 2018 Camaro 2SS A8 Join Date: Jul 2017

Location: East Tennessee

Posts: 11,619

|

Quote:

__________________

2018 Camaro 2SS — G7E MX0 NPP F55 IO6

735 rwhp | 665 rwtq Magnuson TVS 2300 80mm pulley | Kooks 1 7/8" LT headers | JRE smooth idle terminator cam | LT4 FS & injectors | TSP forged pistons & rods JMS PowerMAX | DSX flex fuel kit | Roto-Fab CAI | Soler 95mm LT5 TB | 1LE wheels | 1LE brakes | BMR rear cradle lockout | JRE custom tune 1100 - 1/30/18 | 2000 - 1/31/18 3000 - 2/06/18 TPW 2/26/18 3400 - 2/19/18 | 3800 - 2/26/18 4300 - 2/27/18 | 4B00 - 3/01/18 4200 - 3/05/18 | 4800 - 3/14/18 5000 - 3/16/18 | 6000 - 3/19/18 |

|

|

|

|

|

|

|

|

|

Post Reply

|

|

|