You are browsing camaro6

|

|

#1 |

Drives: 2009 CTS-V, 2008 C6Z06 Join Date: Jun 2017

Location: So Cal

Posts: 91

|

Throttle Body Flow Testing....Results inside

Posted this on the Vette forum recently (that was where a few threads and some debating the merits of different products gave me the "inspiration" to facilitate this test), but seeing as I am helping (and have already helped) alot of you folks here with the same product, all this data is just as applicable and I felt confident alot of you folks would enjoy it as well and wanted to share and keep you in the loop. I knew someone would have posted it here at some point anyway....it might as well be me....LOL!

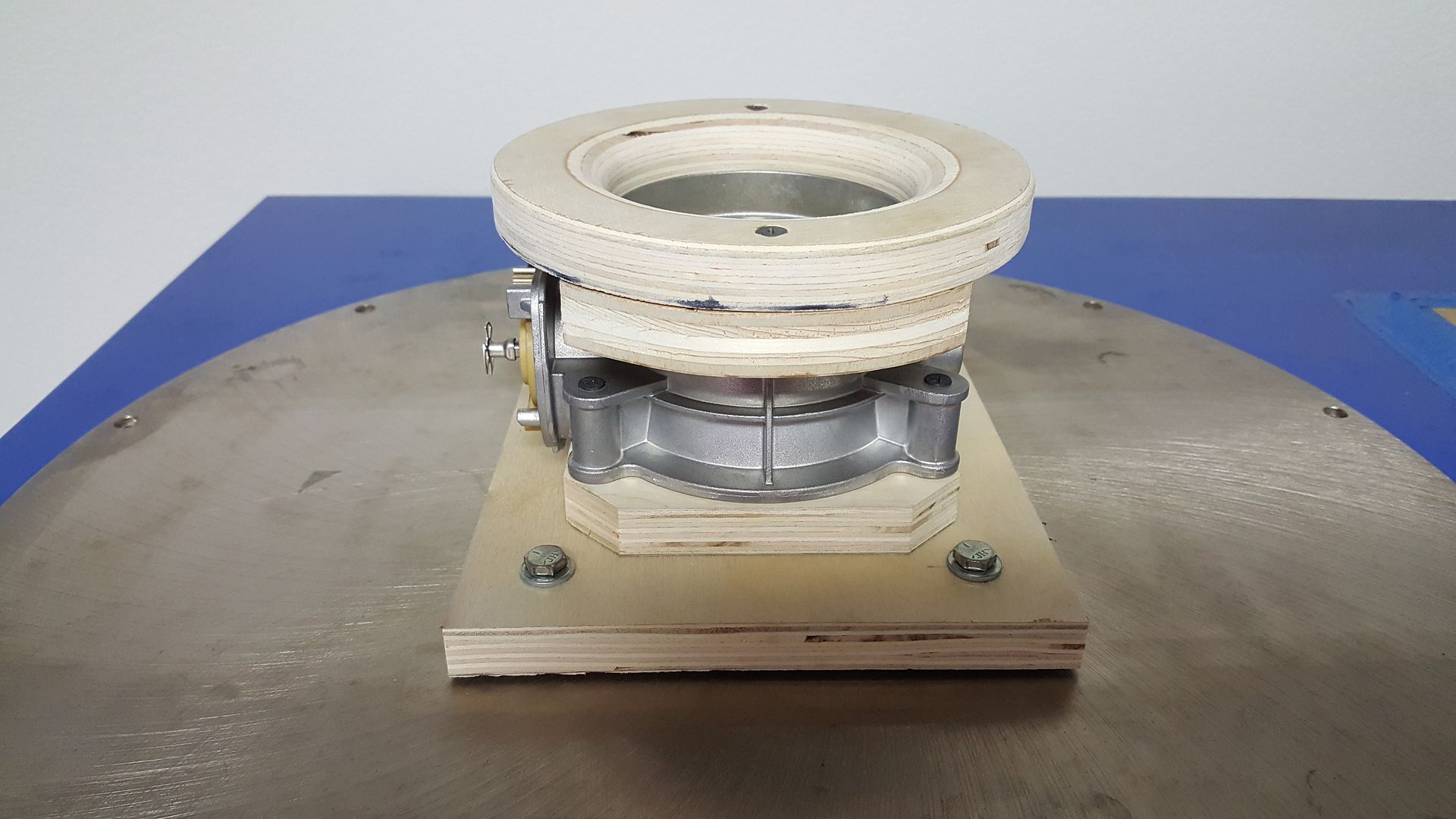

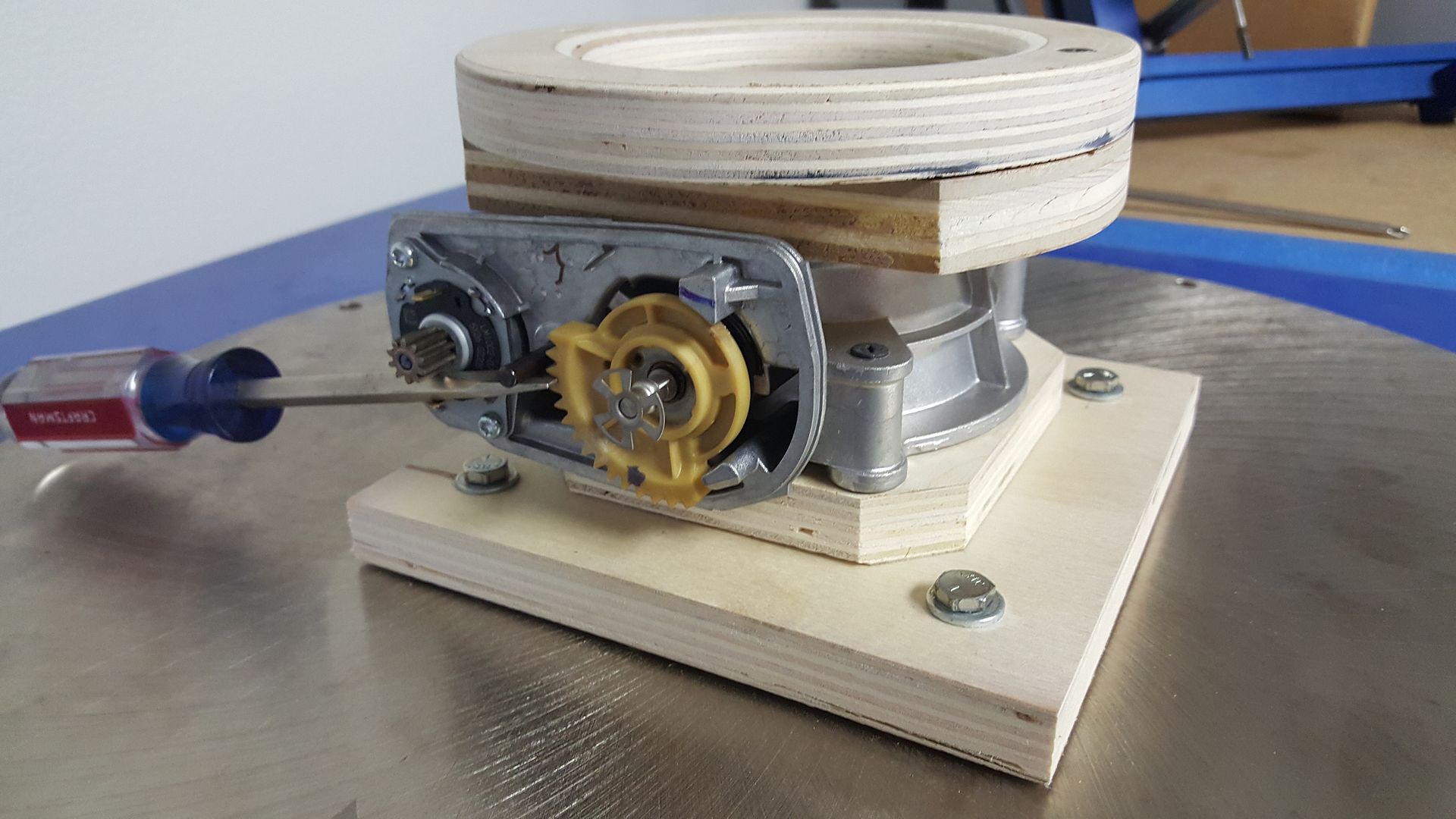

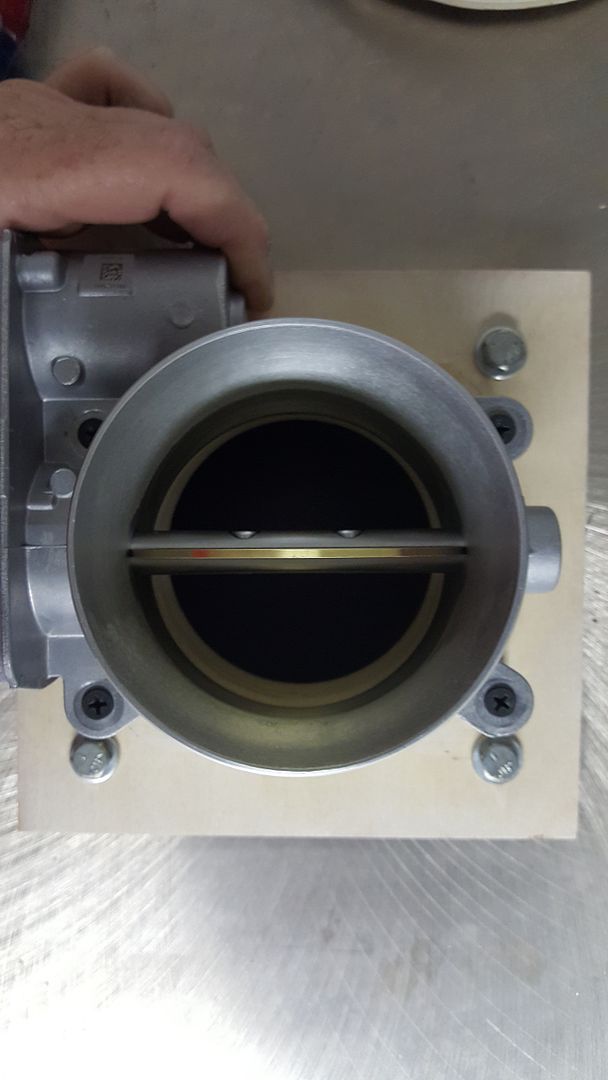

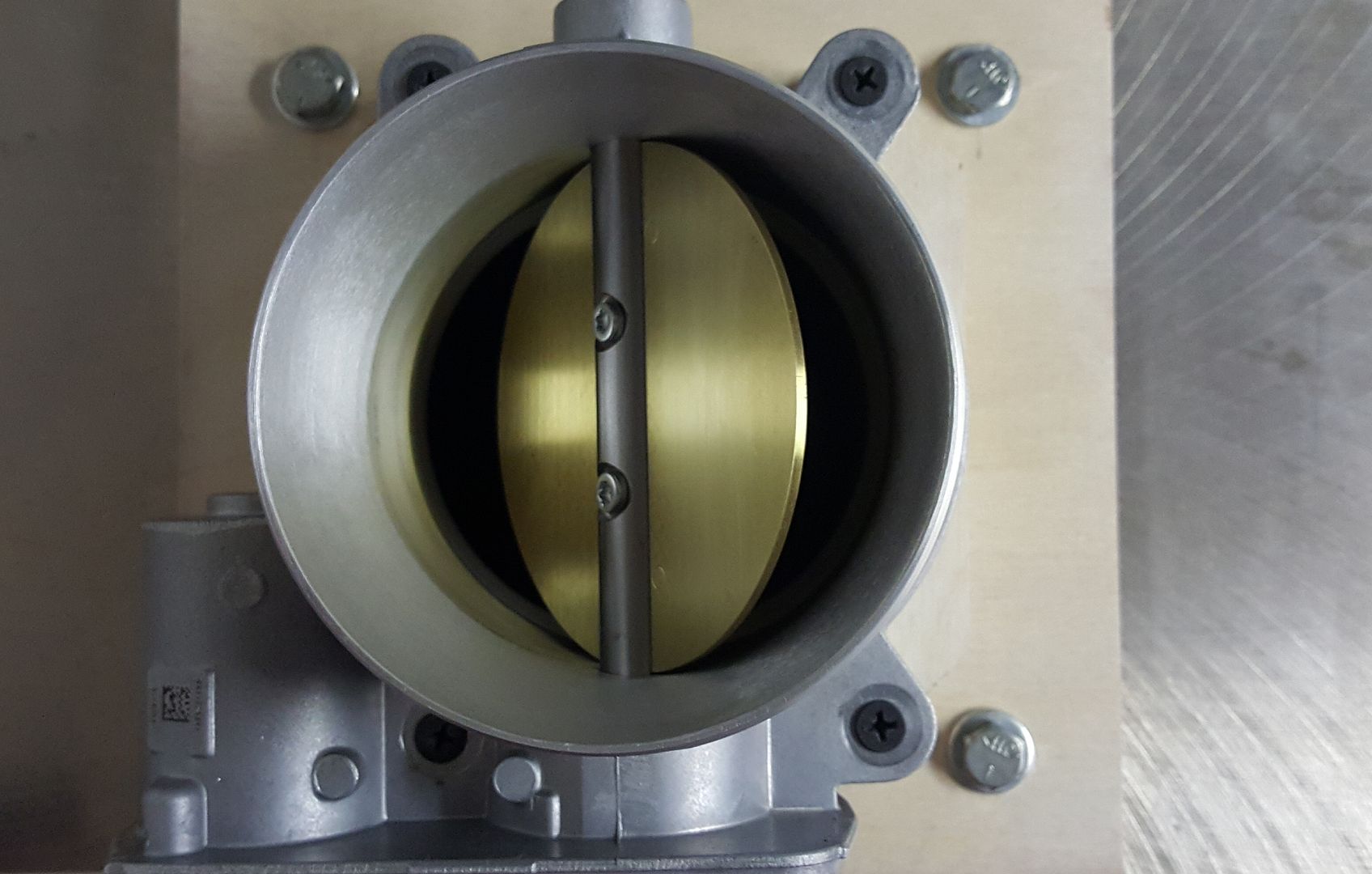

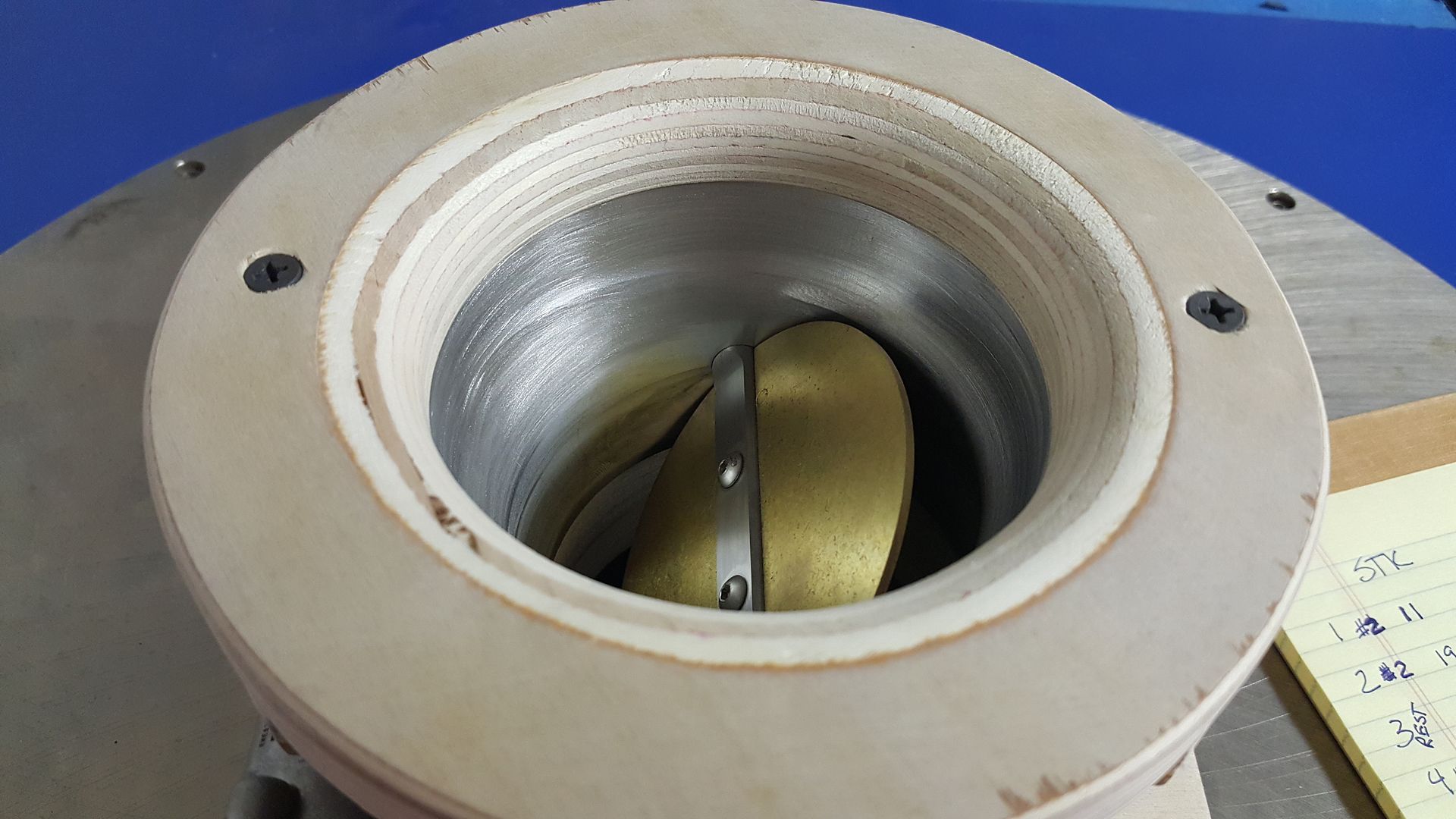

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------- Guys, First off this will be a long post so grab your favorite beverage or visit it at another time when you have more time....if your truly passionate about this hobby and have a thirst for real information, it's worth taking the time to properly take it all in. There have been numerous threads and speculation on this topic (ported throttle bodies....are there real gains to be had or is it a "fluff" mod....comparisons to stock....comparisons among ported units, etc.). In fact it was a recent thread with a bunch of chit chat that sparked my curiosity enough to spend the time to facilitate such a test. Anyone that really knows me knows I don't have the time but I worked even later than my normal retarded hours (driving home a few evenings in daylight the next morning) in an effort to build the fixtures required to gather the data and information some of you (myself included) have been questioning and curious about. The results were interesting to pour over without a doubt but I will say that in general, the shape of the curves were what I was hoping to see and speculated they might look like. BUT....until you see the numbers off the polygraph machine (aka the flowbench), it's all just speculation and anyone's best guess (I just have the advantage of decades in front of the flowbench to formulate mine). But speculating and knowing are two very different things and its nice to get the real world information to validate and back up the theories you may have had regarding all this things in the mix that dictate the end results. To be honest, I was more curious (and not so sure of the outcome) regarding peak flow, comfortable my design approach to porting these units had the stock TB and other ported unit covered everywhere else So what did this entail....I built a radius plate unique to the LT1/LT4's OEM TB inlet size that allowed the airflow to smoothly enter the TB housing bore. Then I built a dedicated base that also perfectly fit the rear/outlet size of the TB and bolted to the base flange that attached to the flowbench. Note that the radius plate is a must have addition as it assures the TB can ingest all the air its capable of perfectly smoothing the airflow into the unit (not shearing over the sharp edge of the TB housing). This is essentially no different than flowing the intake port of a cylinder head for some of you familiar with that operation. It's no different at all in fact and I have built many radius'ed entry's over the last 20 years for the various cylinder heads and intake manifolds I have designed and developed allowing me to properly flow the intake port (or intake manifold) and do so with perfect consistency, not to mention allowing the port (or TB in this case) to achieve it's maximum CFM potential. While on the topic of the radius plates, I should note alot of shop's and private individuals use clay to typically form a "radius" (use that term loosely here) when flowing the intake ports of a cylinder head. To be honest I cringe when I see that....it's extremely inconsistent and the higher the flow (the better the part your flowing), the more it will skew and alter your results in a negative fashion as well as introduce a huge variable in your testing procedures. The real pro's will only used a fixed radius'ed entry whether they buy it (available for more "common" applications from sources like Brzezinski Racing Products), or in this case build it like I did. It can be made of metal, wood, plastic....unobtanium....it doesnt matter....it just needs to be a perfectly fitting radius'ed entry with preferably a 3/4 - 1" radius. Here is a picture of the test set-up....I would have painted it of I had more time but the results and information was much higher on my priority list....LOL  Also, some questions have been asked recently comparing my TB to a different vendor's ported unit. Both are certainly quality products but it's important to understand that there are two very different design approaches taken here and while the peak number in the testing I did was virtually identical (spoiler alert!), the area under the curve....aka ALL your part throttle driving (95%?) was vastly different. It was this situation in fact (wanting to see the shape and comparison of the entire flow "curve") that motivated me enough to invest the 12 or so hours I did building fixtures and figuring out a repeatable way to perform the test....and not just peak flow...I wanted to see the comparison though out the entire range as that's a far more compelling story and drastically effects the way the end user benefits from the product. I have said many times in previous threads but its worth repeating once again....while the gains in peak airflow and added power and torque from the ported TB are excellent (in fact huge gains for the dollars invested), the REAL reason(s) to own one of my ported TB's are the significant gains in part throttle overall responsiveness, a much more linear and intuitive throttle feel, and of course eliminating the dreaded dead spot right off idle that plagues ALL the cars these TB's are installed on. The owners it bothers the most are drivers who have driven enough really dialed in finely tuned performance vehicles that they notice the lag almost immediately. To some it's a minor annoyance....to others it significantly detracts from an otherwise great automobile. All (or most) of this issue can be resolved with the dramatically reshaped and improved throttle bore design of the TB I am helping you guys with. There is another thread with countless independent testimonials backing that up....most of you have seen it already. On to the numbers....but first here is a shot of how I flowtested the TB's at the various blade positions and got complete repeat-ability from one test position to the next. The teeth in that yellow gear providing repeatable results every time and spring loaded so I didnt even have to hold the screwdriver at every "groove" or throttle blade position (not the most elegant solution but hey....it worked!). In fact it couldn't have worked out better as test position "1" is essentially 10% open (just barely above fully closed).....test position "2" was 20% open, all the way to position "10" which was WOT.....the blade perfectly in line with the housing bore (straight up in this test configuration). I liked that I was able to grab ten similar incremental moves from closed to open as it was easy to relate to....position "5" was 50% or essentially half throttle etc. Lets you guys review the data and get a good idea of the type of airflow available at different throttle depressions.  Both ported units showed sizable airflow gains over stock (almost 100 CFM!) and this is why these ported TB's pick up real world power and torque on the dyno.....most guys seeing 10 - 15 RWTQ and RWHP from the various bits of feedback I have gotten (some more but 10-15 is a solid number). Here is all the data Units in CFM at 20" of water (or 1.5" of mercury....same test pressure), which is the generally accepted test depression of carbs and throttle bodies. TB %....Stock TB....Ported TB....Mamo TB 10...........11............12.............12 20...........19............21.............23 30...........36............42.............59 40...........81............104...........124 50...........177..........206........... 228 60...........296..........331........... 355 70...........443..........475........... 506 80...........608..........644........... 678 90...........792..........847........... 872 100.........916..........1003......... 1000 I mentioned earlier in the thread about the design approach to both ported units....its that difference that even'ed up the score at the #10 position (WOT), but at the end of the day the dyno would show identical gains in peak peak when comparing the two (the difference in peak flow so insignificant it could be the related to flowbench repeat-ability), but the gains in area under the curve my design provides will dramatically bolster every other area of the go fast pedal from right off idle to deep in the throttle (but not quite WOT) and everywhere in between. In fact if you carefully review some of the lower/middle throttle positions the gains are just about doubled. Yes.....my TB is a little more money than some of my competitors but the execution is extremely detailed and the extra care and time invested is obvious (ask those who have seen one) and alot of time has been taken to perfect this product shape and function ultimately bringing you the added gains this test validates. I have been designing cylinder heads and intake manifolds for 20 years....TB's are far simpler I assure you although they certainly have their nuances in trying to deliver a product that flows this well and does not have issues with throwing codes. I should mention that's why in the very low throttle positions the airflow is very similar....that's the area Im very careful with as the GM computer seems more sensitive in that region and more likely to throw a code if you screw it up. I purposely leave the lower TB positions airflow very close to stock getting more aggressive as the blade starts to see 25-30% throttle angles. Anyway.....two more hours just drafting this post but I enjoyed seeing the results of this test and was happy with the outcome. Here are a few other pics from the testing today....the first one looking down the barrel of my ported unit being tested at WOT and some pics of the other players being tested as well. I should mention the OEM unit was the loudest on the bench....but not in a good way. The noise was the air shearing off all the OEM sharp edges and ridges in the housing bore....you could tell right away it was unhappy.....LOL    I apologize this post is so long but there was alot to go over and I wanted you guys to better understand how I did it, why I did it, and the science that went into gathering all these figures. I hope most of you reading enjoyed it and found it informative....if you have any questions fire away and I will respond some time this weekend in between handling some engine building chores (finishing up a 454 LS engine with my new LS7 MMS 265 heads that's headed to the engine dyno next week!). Catch you guys later!  Cheers, Tony |

|

|

|

|

|

#2 |

|

Use the Force

|

Thanks for the detailed explanation, especially why the first 25% is close to stock figures.

__________________

Walk softly, carry a light saber and drive a ZL1!

|

|

|

|

|

|

#3 |

Drives: 2017 ZL1 A10 & 2021 BMW M340i x Dr Join Date: Mar 2009

Location: Tampa

Posts: 5,110

|

Nice write up. Now that you created a way to test the flow, will you be testing the new TB's you provide for consistency?

__________________

Sold 2012 2LT RS 12.3@112 old setup

Sold 1967 Camaro Pro Street. Ran 10's mild BB on NOS. 2017 HyperBlue ZL1 A10 ** Born 3/17/17**Delivered 4/08/17 2020 Build: Mag2650, BTR Stage2, NW103, BG, 14% lower, 90mm upper, ARH 2" Long system w/no cats, SW Legend mufflers. **807hp/762tq on 93 gas** and **848hp/792tq on e47** Sold 2018 (Go Mango) Dodge Charger Daytona 392 Daily Driver Daily Driver 2021 BMW M340i Xdrive |

|

|

|

|

|

#4 | |

Drives: 2009 CTS-V, 2008 C6Z06 Join Date: Jun 2017

Location: So Cal

Posts: 91

|

Quote:

Its a good question but I wanted you to know how I have handled it thus far and shipped at this point probably a couple of hundred units with a very high level of success (a few issues on some finicky C7 Vettes). The ZL1 seems just the opposite I might add...very few if any issues in this platform....the tolerance in the tune must be a little looser in the ZL1 applications or at least that's my working theory....LOL Regards, Tony |

|

|

|

|

|

|

#5 |

Drives: Current driver AMC emlin X 5ltr. Join Date: May 2011

Location: None-Ya

Posts: 250

|

Great information Tony. I can't wait until you contact me saying that mine is ready to ship

|

|

|

|

|

|

#6 |

|

"BEASTM*DE"

|

Great write up...

__________________

Vengeance Racing Stage 1 Kit 575rwhp, 569 rwtq...

Rims powder coated gloss black...BFG'S Comp 2 A/S... Dual 10" Kicker Comp S Subs 1200w...  |

|

|

|

|

|

#7 |

|

Very good information here. So how much does this cost?

|

|

|

|

|

|

#8 |

Drives: 2017 Camaro ZL1 M6 pdr roof CF blk Join Date: Mar 2017

Location: MA

Posts: 252

|

Nice work, enjoying your TB Tony and love how it feels, car is an animal

|

|

|

|

|

|

#9 |

Drives: 17 NFG ZL1 17 GTR 22 RS6 Join Date: Apr 2017

Location: Upper Marlboro MD

Posts: 625

|

Tony thanks for taking the time for both this thread write up and the testing!!! As a happy customer of your TB, it brings me joy to wake up and dig into info like this. I didnt have one iota of regret in this purchase as the butt dyno along with negating the dead spot spoke for itself. Now I just feel like I brought from someone that cares about the product he produces and the customers knowledge of said products. I'm a customer for life. Thanks!!

|

|

|

|

|

|

#10 |

Drives: 2017 SS 1LE Mosiac Black Join Date: Nov 2016

Location: DFW, TX

Posts: 1,132

|

Are the LT1 and LT4 TBs the same?

|

|

|

|

|

|

#11 |

Drives: None Join Date: May 2017

Location: Chicago, IL

Posts: 462

|

|

|

|

|

|

|

#12 | |

Drives: 2017 ZL1 Join Date: Aug 2016

Location: Long Island, New York

Posts: 1,036

|

Quote:

|

|

|

|

|

|

|

#13 |

Drives: None Join Date: May 2017

Location: Chicago, IL

Posts: 462

|

You shouldn't need a tune, although you might have to have him port one a bit conservatively as to not throw codes. Some people have issues, others don't . . . the ECU seems to be a bit finicky.

|

|

|

|

|

|

#14 |

|

I have the Roto fab- Tony's Throttle Body and mufflers, no issue here.

__________________

|

|

|

|

|

|

|

|

|

Post Reply

|

| Thread Tools | |

|

|